High performance, high edge-angle skiing puts increased demands on tuners to properly prepare the side edges, side walls, and the top sheets. Why? Because the racers spend a lot of time with the skis laid over and NEED performance out of the side of the skis- not JUST the bases.

This blog entry supports this document:

Tuning Standards.pdf

Sturtevant's and World Cup already have these specs and this info. I will also offer them to other shops who are willing to support us in this way.

This is advanced tuning work. I have taught the techniques individually and in clinics, and I will do so again this winter for those interested. As tuner extraordinaire Blake Lewis says “Proper sidewall removal and shaping is an art unto itself.”

In this post, I will discuss:

1.) Which racers/skiers need extreme sidewall tuning and which will benefit from a more moderate approach

2.) How to tell if the skis you are working on need more attention to the side wall

3.) How to setup side walls and top sheets on new skis

4.) How to repair sidewalls on older skis.

5.) Problems with over-tuning the sidewalls

6.) Cap ski tuning

7.) Suggested tools

8.) I have included links to a few videos that I believe to a great job of explaining the process.

9.) Longer Answers

Short Answers, more details to follow:

1.) Which skiers need Extreme Sidewall treatment?

Only the U-16 and FIS racers who may be invited to a Western Region Camp or above need the most extreme sidewall treatment. Reasons for this logic will be explained in the LONG answer section.

This is a FIS level sidewall. There is still SOME shoulder, but it is radically reduced, rounded and blended into the sidewall. You can see the radius by comparing to the shaping block

1a.) Which racers would benefit from a more modest treatment?

Racers up to the U-16/FIS level are better off with a more modest treatment. It will NOT slow them down, but it will preserve ski life and reduce ski setup/tuning time/cost.

This is an example of a Junior level sidewall. The shoulder is relieved, and the sidewall is smooth. It is easy to file, but still very strong.

2.) How do you tell if your skis need more sidewall attention?

If you have to ask, they probably need attention, but the easiest way to tell is by coloring the edge with a black pen in a few spots, then run your file/edge guide over those spots ONE time. Look where the pen markings are removed. If the ink is still on the shoulder above the edge, you may not NEED to remove more sidewall- but you may want to. See long answer for explanation.

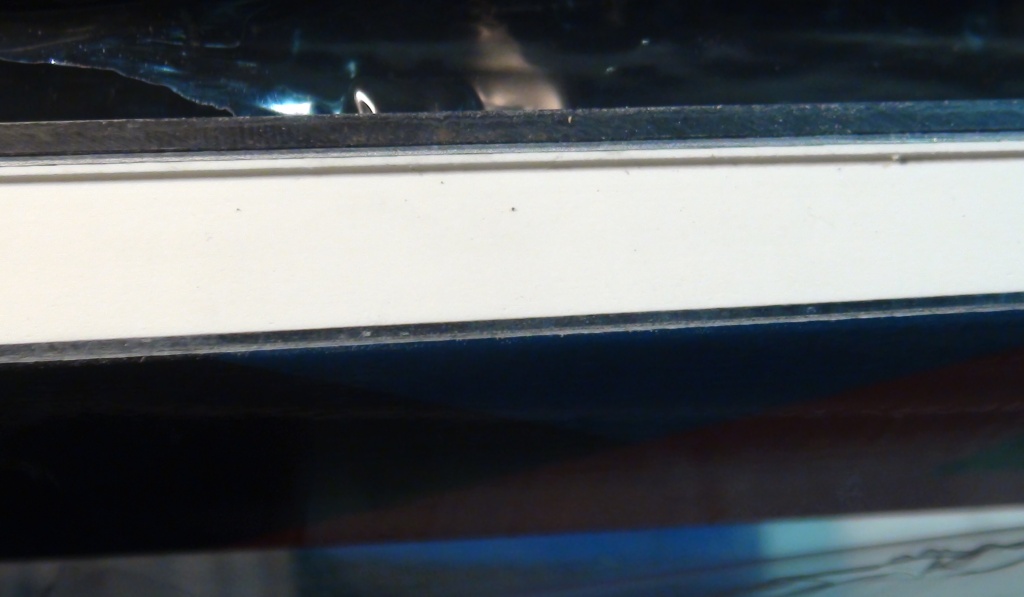

These pictures show a FIS level, brand new pair of skis. Notice the shoulder above the edge is pronounced, the sidewall is square and a bit rough, and there are still grinding marks on the skis. This is a typical new ski finish from the factory. Lots of remaining speed potential here!

3.) How do you setup new skis?

Top Edge: Start with a Panzer or other very coarse file that will remove a lot of material quickly, working on the Top Edge of the ski. Round the top edge substantially, then smooth, blend and de-burr your work with a finer file. Finally, sand the top corner smooth. Side Wall: Start with a sidewall planer, following be a backfiler (which is a high-degree file guide with a coarse file in it) followed by sandpaper. For FIS level, further smooth with Scotbrite and finish with wax/polish.

The big panzer file can do a lot of work, or a lot of damage REALLY quickly. Gloves must be worn, and it requires a couple of strong, confident hands. After the rough cut of the panzer, smooth and blend the top edge with a finer file and sandpaper.

Next step is the sidewall planer. For this picture, I have it set to remove maximum plastic sidewall and minimum bottom laminate of the ski. It is safer and easier to use if you set it to remove smaller amounts of material with each pass.

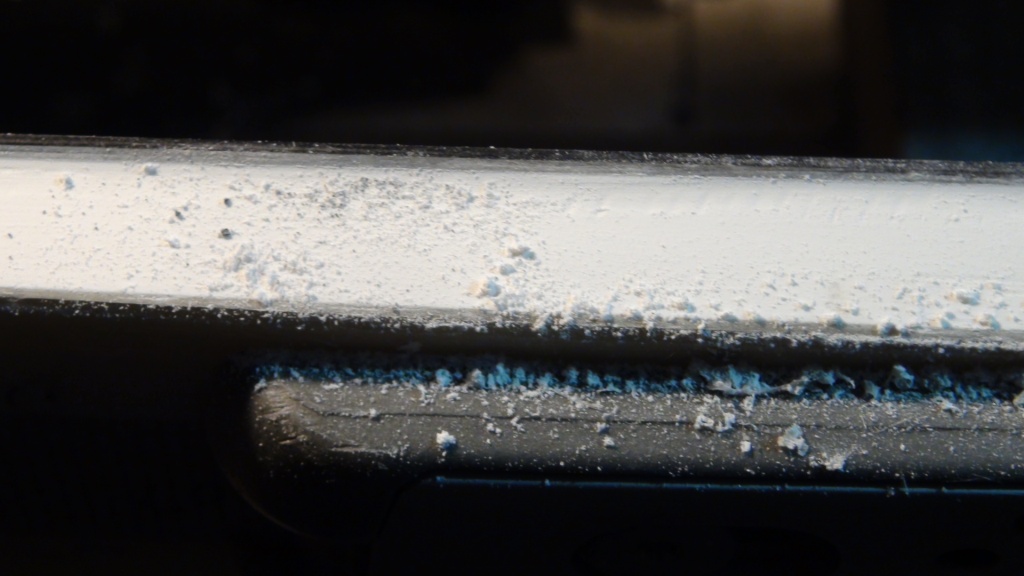

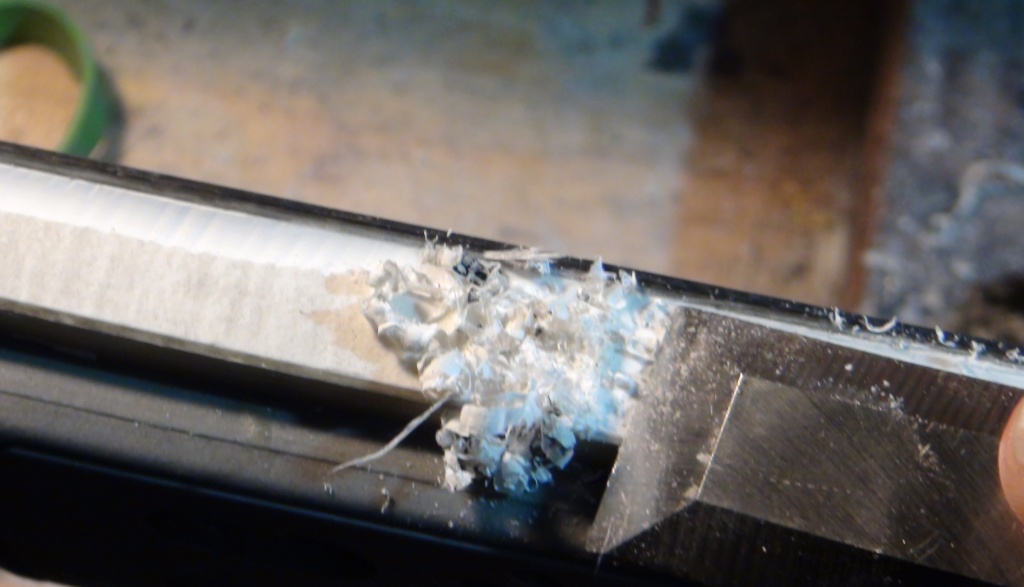

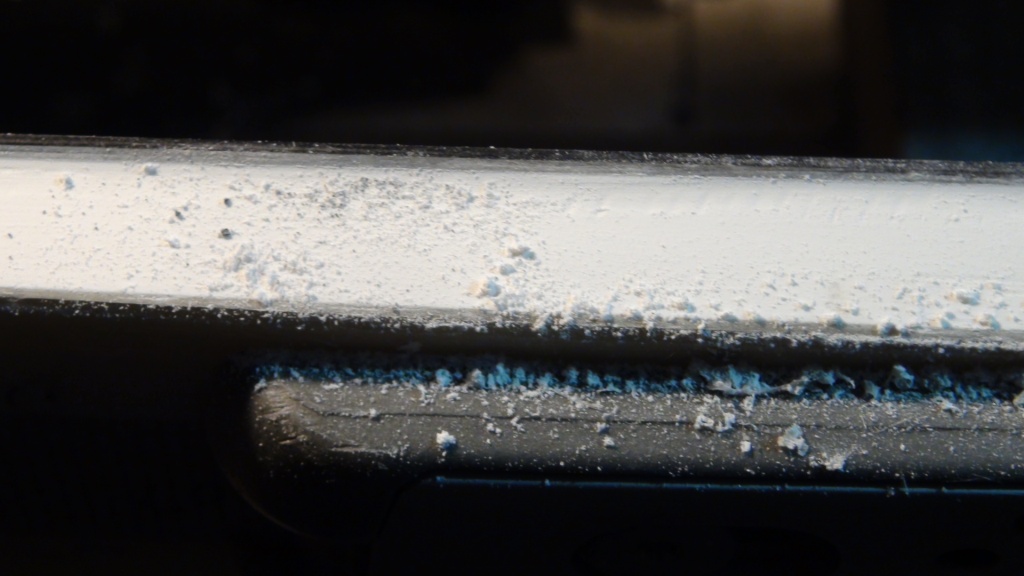

This is a big of the sidewall dust you can expect while doing this work. Phenolic sidewalls create a fine, choking dust not unlike drywall. A vacuum should be used for cleanup, and a dust mask for personal protection.

This is a purpose- built shaping/sanding block made from a 1x2, 3 inches long. It has a radius of 1" on the corner that contacts the shoulder of the ski. Use it with 180-220 grit sandpaper to blend the sidewall.

This was the goal: A radically reshaped sidewall and top edge (in this case) for a FIS GS ski. This will be an easy ski to sharpen and maintain.

4.) How do you repair sidewalls on older skis?

Top Edge: Smooth with fine file followed with sand paper. Sidewall: You may be able to use a sidewall planer to remove more material, but if the edge is already flat against the side, you will have to "trench" into the sidewall to gain access to the last bit of useable edge. Once this is done, you will need to remove more sidewall and top edge so that the ski will not hit the sidewall and skip off of the edge. This is time consuming and a little dangerous to fingertips because you must hand hold a small, sharp file flat against the sidewall and remove much of it. A sharp wood chisel can also be used (very carefully)- but the BIG requirement is patience. This is a tough job.

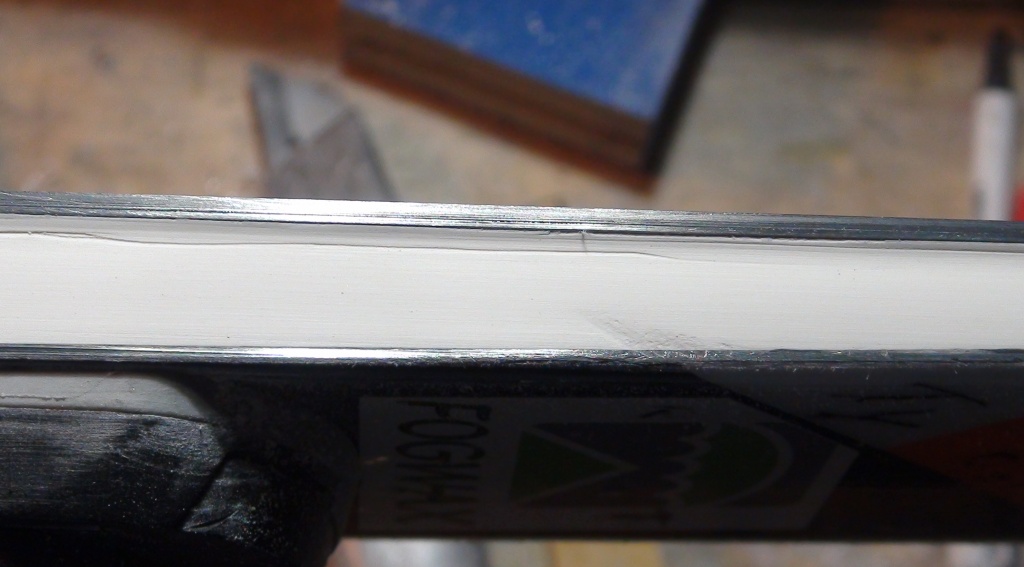

This is a worn ski after sidewall removal and backfiling, but has not had much blending work done yet.

5.) Problems with over-tuning:

It is unusual for a ski with the entire shoulder removed to last an entire season. For sponsored athletes (or those with large equipment budgets) this may not be a problem, but most racers need a pair of skis to last A FULL SEASON, if not longer. The shoulder above the edge is NOT a manufacturing mistake, it was designed into the ski to provide strength to the edge. Think carefully before cutting away more sidewall than you really need, otherwise you may not have good skis left (unless you buy replacements) by the time the Spring races roll around. Over-beveled edges dull faster, can bend more easily, and even delaminations along the edge can happen to unsupported edges when the sidewall is removed. The most common problem is just running out of edge to work with.

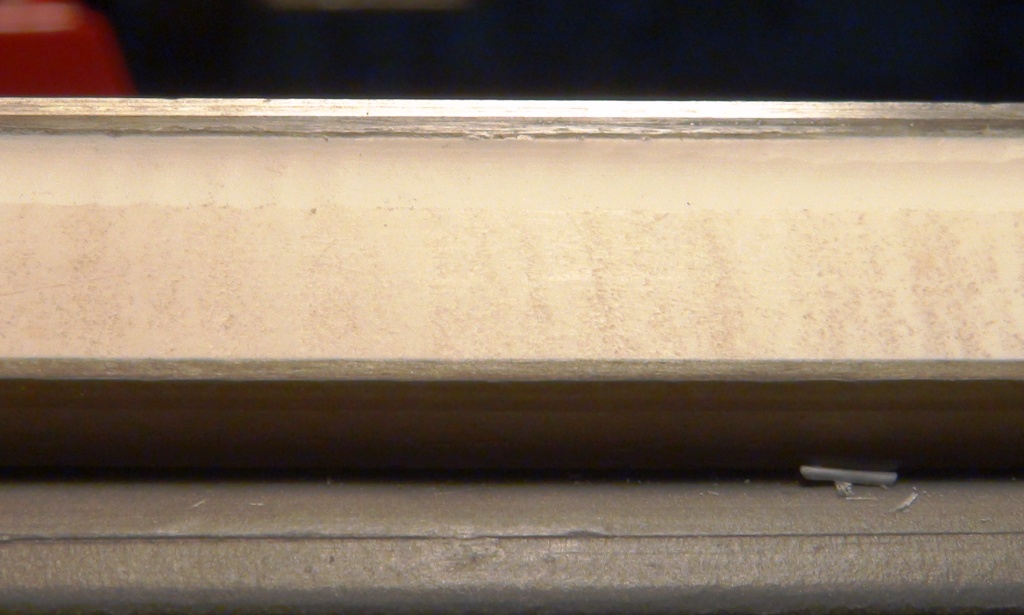

This is an edge on a ski with about 1/2 season of use. The edge is already super thin. Top racing skis have very thin edges. They are built for performance, not durability. If you want your edges to last a full season, you must actively preserve them through tuning method and planning.

This is a ski that has been filed so much that a trench had to be created to get access to the edge. To finish this ski properly, the rest of the sidewall (the flat, non-trenched area) must also be removed and the top of the ski must be reshaped.

This is the debris from ONLY 3 PAIRS of skis- sidewall removal is messy and time consuming.

If you haven't noticed how much work this is, then I haven't done a very good job with this post. Most people should hire this work out. You will be happier in the end.

6.) CAP SKIS!!!

It is easier to tune the sides of Cap Skis because the tops are already shaped for you. All you need to do is plane the shoulder off below the edge and blend it into the sidewall. Do NOT use a Panzer file on the sides of a cap ski. Sandpaper should be enough. So New ski are easier. But old skis (on the other hand), when you run out of edge on a cap ski, the ski is done- there is nowhere to go. The sidewall is thin and cannot be worked.

Here is the sidewall removal on a cap ski. They are easier to shape than a laminate ski.

7.) Suggested Tools:

This list will be updated with a few more tools in the next couple of days...

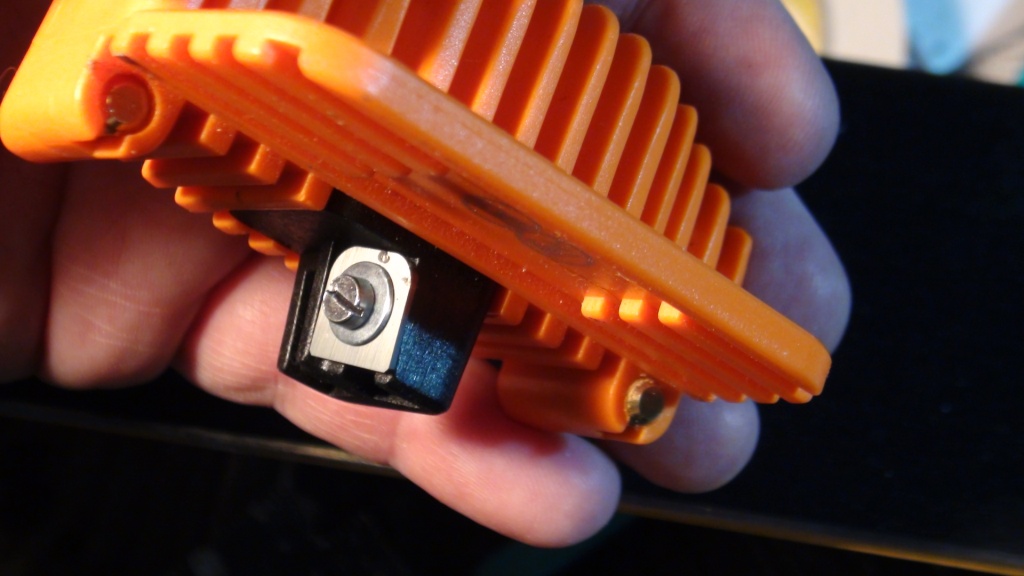

This is a classic sidewall tool. It has a rounded cutter which works the best on laminate skis.

This is a combination square and rounded-edge sidewall tool. The square edge works best with cap skis.

8.) Videos:

I shot some of my own videos this fall- but it is a TON of work, and not much fun for me, so I would rather point you to some good videos that already exist. Start Haus has made a Great Series of videos that I highly recommend. Here is one...

Start Haus:

https://www.youtube.com/watch?v=UPPP158_Wpg This is a very good video and they have produced a complete series which is all very well done.

Other Sidewall videos- useful, but NOT as good in my opinion.

Toko video showing Basic removal: http://www.toko.ch/en/usage/application-videos/alpine-skis-and-snowboards/sidewall-tuning-videos/tuning-sidewall

Aggressive removal from Swix: https://www.youtube.com/watch?v=AdPw8VmwDCQ

Edge Beveling: https://www.youtube.com/watch?v=Pj6rM8riEoQ

9.) Long Answers:

Why are we pushing for a standard for FIS tuning? The answer lies in how the top racers in Western Region and above are skiing these days. They are laying the skis ALL the way over and contacting their boots, knees and hips so their skis MUST be tuned in such a way that they will hold even angled beyond 90 degrees. The Western Region coaches understand this and are instructing their racers how to tune this way. We want all racers who may be skiing and coached at this level to have their equipment fully ready so that they can take full advantage of these great opportunities.

Why don’t we tune ALL skis this way? As a consumer, it is up to you if you want to have all your families’ skis setup for the FIS standard. But you should understand that this is an expensive choice and may provide little or no benefit to you or your racers at a lower level. The ski companies and stores more than happy to sell you more gear, more often. Do want to buy gear twice as often? At the highest levels, Slalom Skis only last around 10 days on snow. If you have a full-ride sponsorship, it may be no problem- but for the rest of us, changing slalom skis 3-5 times/season is a substantial additional cost.

Additionally, there is a not-unimportant safety issue to consider: Young (u16 and below) leg muscles, bones and joints are not nearly as strong as 18-25 year old racers’ legs and joints. Skis that hook up super hard can get them into trouble that they might not ski out of, and injuries can be the result. I believe the BEST choice is to save the Most Aggressive Tunes for ONLY the Most Aggressive Racers that NEED them.

Why do we have a Standard for Mighty Mites and Juniors? Because these racers also require their skis to perform properly in order for them to learn proper ski racing technique and tactics. Flat bases are especially critical to learn how to roll over a ski and carve a turn. These standards are intended to help parents provide what their kids need, and to help local shops provide the level of service that is appropriate to all our racers. Better for the kids, better for the shops (and home tuners), and better for the Parents- Win, Win, Win!

I am moving on from this post now, but I am happy to answer any/all question. Please drop me a note.

-Gadget